Processing

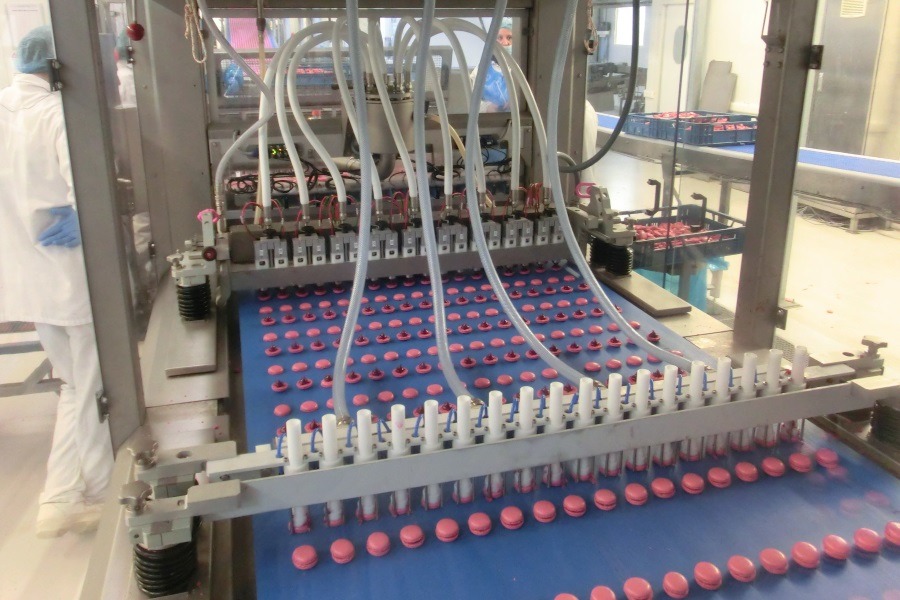

Capper Large

Industrial version for continuous production in connection with an oven tunnel

The machine is directly connected to an oven and installed after the cooling conveyors area. The following operations are completed automatically :

Distribution and alignment

Rows & lanes preparation

Rows tilting

Row synchronization with dosing & capping

Dosing of filling

Capping

A personalized support

In order to define the machine the most adapted to your production

01

Machine feeding with flat products on the belt or with stacked products via loaders

02

Dosing via manifold or hopper depending on type of fillings and/or speed

03

Option no product / no dosing

04

Cream feeding in simple or double jacketed

A dedicated solution

Discover all the benefits of our customizable solutions for your production system

A complete solution, personalized for industry professionals.

Capper sandwiching machine – Capper Large

What are the benefits ?

A turnkey production system

- A fully automatic turnkey solution

- Rigorous and precise production

- Robust construction, stainless steel frame, without mechanical parts under the process area

- Automatism provided by PROCYS

Flexible production system

- Dosing and capping head motions are controlled by brushless motors allowing a movement adapted to each recipe with maximum flexibility

- Modification of settings during production with different access levels for operators, line manager or maintenance technicians

Innovative production system

- Machine controlled from a touch screen, recipes storage (dosing/capping motions)