Handling

Stacking systems

Action of stacking products. This process is necessary before a manual pick-up table or before feeding machines such as traditional sandwiching machines or some packaging machines

PROCYS offers the complete environment

Lane multiplication / reduction

Putting back into lanes

Grouping / batch preparation

Distribution / transfer / tilting

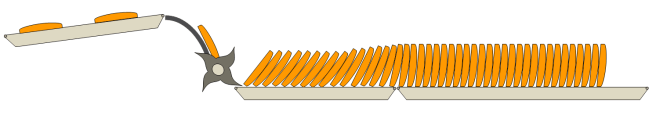

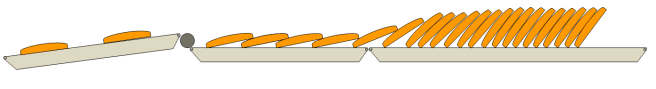

How does it work ?

01

Arrival of the biscuits flat on the full belt

02

Positioning of the biscuits between guides via a channeling board

03

Stacking the biscuits to arrange them on edge

2 possible technologies to arrange biscuits on edge

We can help you to define the most appropriate solution for your production line considering the product, its capacity and application.

PROCYS determines the most suitable solution according to the products, the rates, the application etc.

The Rotary stacker

This technology makes it possible to work with independent lanes, the orientation of the biscuit is more vertical.

The Penny stacker

This technique is adapted to faster rates and is usually more flexible when there are format changes.

Build a complete environment with our engineers to optimize your food production line.

Stacking systems

What are the benefits ?

Reliable and flexible production system

- Modular rates

- System adaptable to the type of product

- Delicate handling of products, no damage to fragile products

Agile implementation

- Automatic connection with your traditional sandwiching machines

- Automatic connection with your packaging machines

- Accumulation possible with mobile stackers