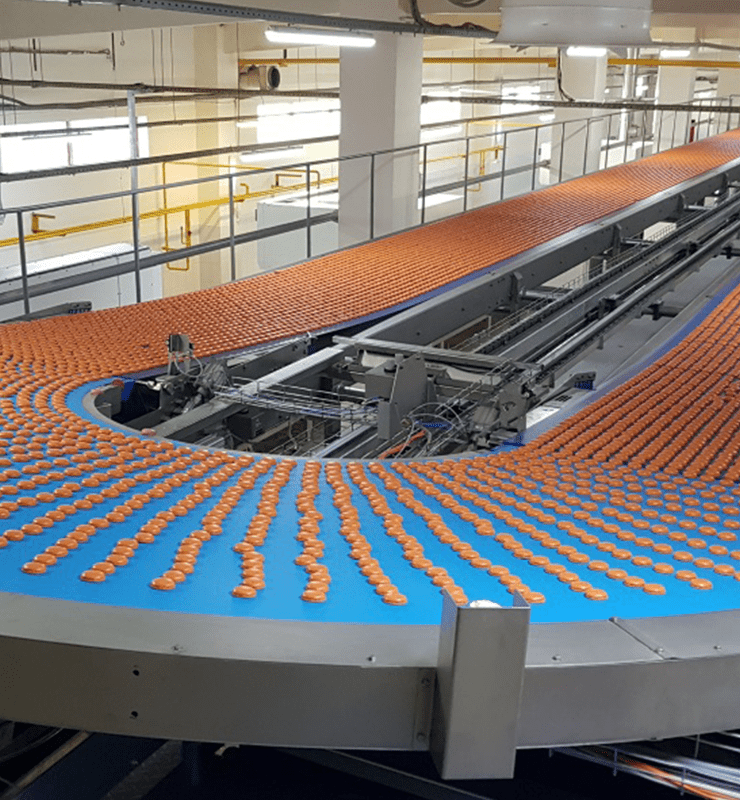

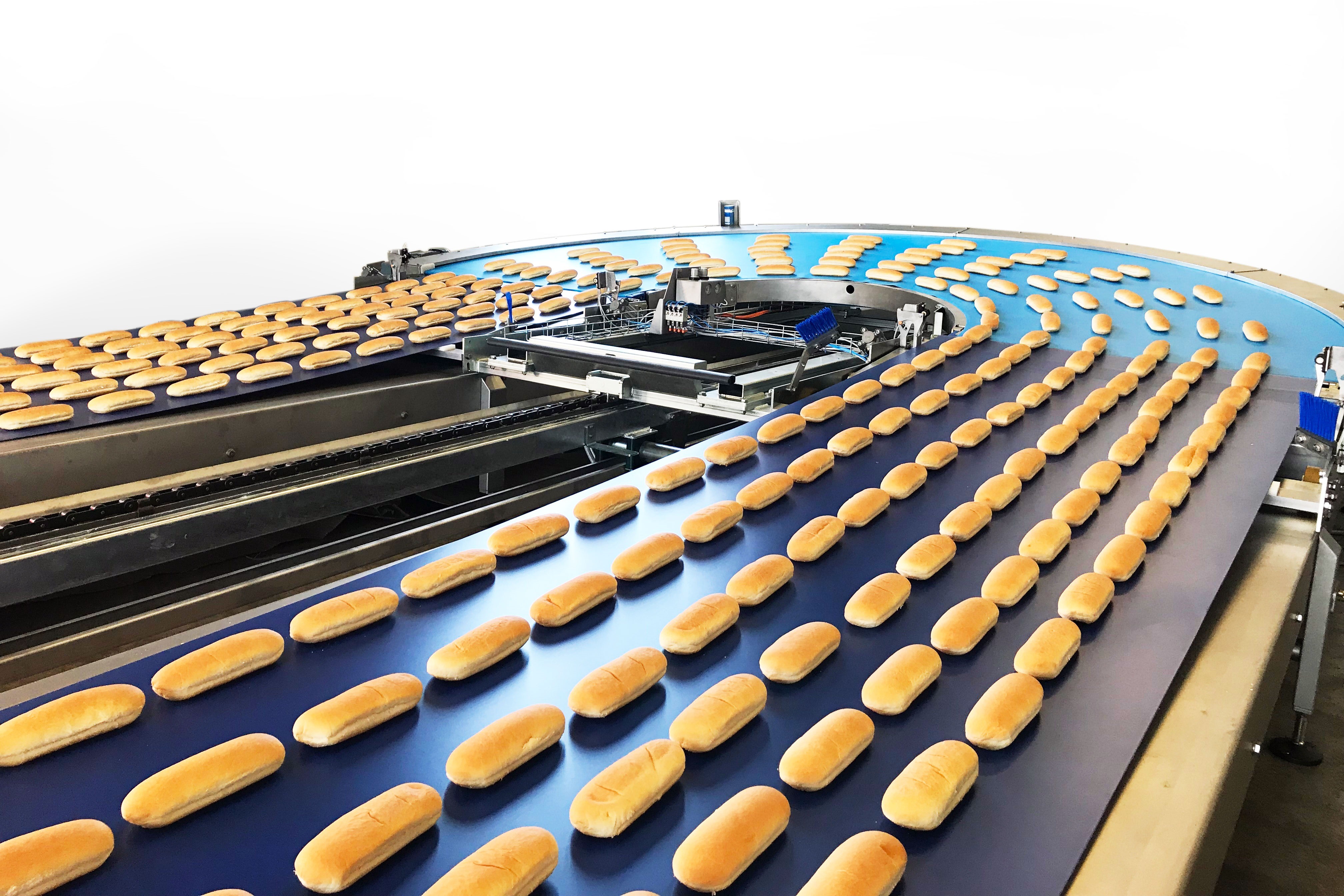

Buffer systems

U-shape buffer

The dynamic accumulator makes it possible to accept input production at a different rate from output production.

During the phases of stopping the packaging, the production continues at the same rate and the accumulator is responsible for accumulating the products. The packaging machines then operate at a slightly higher rate to absorb the accumulation of products.

After 15 years of experience in the manufacture of dynamic buffer systems, PROCYS has developed and patented a technology without lifting rollers that maintains the stability of the products by avoiding the “wave” effect of the belt between each roller.

Optimize your production line with an U-shape buffer

Separate the operation of a manufacturing unit from the packaging area

Maintain the same pace of continuous production during packaging downtime

Reorganize the products in the same operation

Make product feeds independent

Carry from input to output, a production at different rates

How does it work ?

The system is made up of 2 belt conveyors and a 180° curve mounted on a mobile carriage driven by a Brushless motor. The variation of the accumulation capacity takes place with the displacement of the curve.

01

During a machine shutdown: arrival of the rows of products on the accumulator, the empty spaces are detected, using a cell installed at the entrance.

02

Automatic shutdown of the infeed belt until the arrival of the next row of procuts, in order to fill the voids and thus optimize the accumulation capacity.

03

Moving the trolley to allow accumulation.

04

When the production is released, the packaging machines pace accelerates slightly in order to absorb the accumulated products.

Create with our engineers your own tailor-made buffer system that meet your requirements and your needs.

U-shape buffer

What are the benefits ?

Food safety ensured

- No contact to products

- No preservation issues (FIFO : First In First out)

Customizable production system

- Length, width and rhythm adaptable according to the need for accumulation and the available space

- Possible aerial positioning

- No mechanical tools required

Flexible production system

- Suitable for multi-format lines and different products

- Possibility to adjust products accumulation